Decoding Plastic #1: The PET Bottle Saga

Plastic No. 1 is likely the most talked-about type of plastic today, and rightfully so—it’s the most widely used plastic across the globe. But have you ever wondered what that number 1 inside the recycling symbol actually means?

Well, you’re in the right place. I’m here to help you understand and learn more than you currently know about Plastic #1. Let’s dive right in.

The Complete Guide to Understanding Plastic #1 (PET)

Let’s delve into the essentials and cover everything you need to know about the most widely used plastic in the world today. We’ll even break it down into simple terms, answering the questions you’re rightfully asking.

Understanding Plastic #1 (PET)

Plastic #1 is Polyethylene terephthalate, commonly known as PET, the most prevalent plastic you’ll encounter. Invented in 1940, it has become a fundamental component of our everyday lives.

Widely favored in the packaging industry, PET is renowned for its lightweight, clear, and recyclable properties, making it a popular choice for a variety of applications.

Recognizing Plastic #1 (PET) in Everyday Items

Identifying PET is straightforward. You can usually spot it by looking for the recycling symbol with a small number ‘1’ inside, often located at the bottom of containers.

This is the plastic resin code for PET. It’s typically clear or slightly tinted, with a slight shine, and is known for being sturdy yet slightly flexible.

Common Uses of Plastic #1 (PET) in Containers and Packaging

Polyethylene terephthalate, or PET, is a versatile material that’s extensively used by manufacturers for a wide array of products. PET can be found in everyday items such as water bottles, soft drink bottles, and various food containers. But its presence extends far beyond just these.

PET is the material behind many commonly used items, including:

- Beverage bottles for soft drinks and water.

- Food jars, like those used for peanut butter.

- Salad dressing and cooking oil containers.

- Packaging for detergents and personal care products like shampoo, conditioner, and soap.

- Pharmaceutical and medical supplies, ensuring products are kept safe and hygienic.

- Household items such as bean bags, ropes, carpets, and fillings for pillows and sleeping bags.

- Textile fibers, which are prevalent in clothing, linens, and other fabric products.

Its typically clear or slightly tinted appearance, combined with a sturdy yet flexible nature, makes PET a preferred choice for a variety of packaging and product manufacturing applications.

The Safety Profile of Plastic #1 (PET)

PET, short for Polyethylene Terephthalate, is generally considered safe for food and beverage storage, with no known health issues arising from the material itself.

Despite the abundance of contradictory information, to my knowledge, there are no studies definitively proving any dangers associated with PET in food-related applications. However, as a precaution, I never reuse drink bottles. They are designed for single use only.

Moreover, I strongly advise against using cooking bags made from PET. These are subjected to high temperatures, raising potential concerns about the risk of chemical migration during each cooking process.

Regarding the reuse of PET containers, it’s worth noting that although they are safe for single-use applications, there are risks associated with repeated use. Over time, PET can wear down and may potentially leach chemicals, especially if not cleaned properly. This deterioration also increases the risk of bacterial growth, which can be potentially harmful. So, while PET is a convenient and generally safe material, it’s important to use it as intended and exercise caution with repeated use.

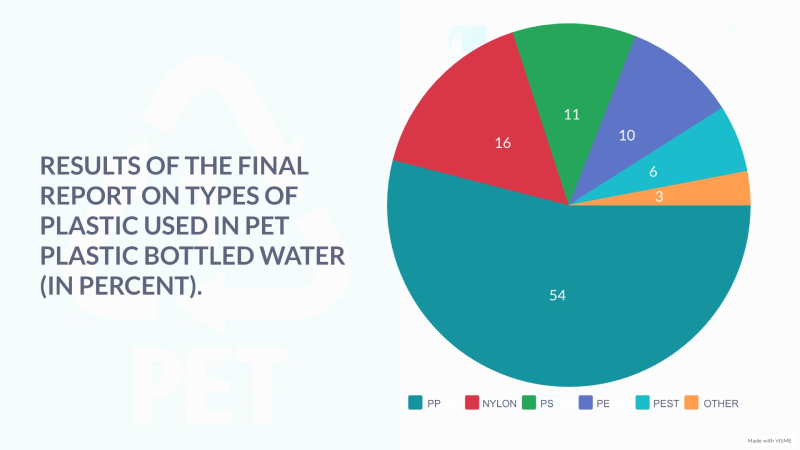

A study on water bottles and the presence of micro-plastics

Since PET plastic is used to manufacture water bottles, I also encourage you to look into the following study. Conducted by Sherri Mason, a professor at the State University of New York at Fredonia, its summary was published on the media platform Orb Media.

Overall, the study demonstrates that tiny particles of plastic have been found in bottled water from many major brands around the world. This finding comes from a test conducted on 259 bottles from different batches, among 11 brands purchased in 19 different locations across 9 countries.

Results of the Final Report on Bottled Water in PET Plastic

As highlighted by the study, 93% of bottled water showed signs of micro-plastic contamination. Polypropylene was the most common polymer found (54% – often used in bottle caps). This was followed by nylon, polystyrene, polyethylene, and other materials.

- PP = Polypropylene

- PS = Polystyrene

- PE = Polyethylene

- PEST = Polyester + Polyethylene Terephthalate

- Others = Azlon, Polyacrylates, and Copolymers.

I think it comes from the bottling process. Most of the plastic likely originates from the bottle itself, its cap, and the industrial bottling process. In the water from glass bottles, there were also micro-plastics.

Sherri Mason, Professor, State University of New York at Fredonia.

Alternatives to Plastic #1 (PET) for Eco-Friendly Packaging

While PET is a highly efficient option for plastic packaging, it’s not the only choice. Let’s explore other materials like polypropylene, aluminum, glass, or paper.

Polypropylene (PP)

Polypropylene, often used in reusable food containers and microwave-safe storage, stands as a viable alternative. It’s commonly seen in a variety of packaging solutions due to its versatility and durability.

Raw Paper and Cardboard

Raw paper and cardboard, more biodegradable than PET, face challenges in food packaging. Indeed, often combined with plastic or aluminum laminations, they become non-recyclable and end up taking more space in landfills.

Additionally, their production demands more energy, generates more waste, and involves tree cutting, with a heavier weight impacting transportation emissions.

Glass

Glass requires high temperatures for manufacturing or recycling, resulting in significant emissions—up to 4.5 times more than those from producing PET bottles.

Its heavier weight also leads to a larger carbon footprint during transportation, making rPET bottles a more environmentally friendly option due to their lighter weight.

Aluminum

Aluminum, while recyclable, requires intense resources for production and recycling. The manufacturing process demands high temperatures, leading to more emissions.

Even recycled aluminum cans produce more CO2 per ton than PET bottles, highlighting the environmental cost of this material.

Guidelines for Recycling PET Plastic

Recycling #1 PET plastic has become quite straightforward, as most recycling centers now accept it.

However, it’s always a good idea to:

- Double-check with your local authority

- Consult the Earth911.com website: by entering your locality and zip code on their site, you’ll receive specific instructions on what to do.

If you’re interested in learning more about this topic, I invite you to read my other article titled ‘Is Plastic Number 1 Recyclable?

The Process of Recycling Plastic #1 (PET)

To help you understand the recycling process better, let’s take the example of PET bottles. Here are the different steps involved in their recycling:

Step 1 – Collection

After being sorted by consumers, PET bottles are collected and transported to a recycling facility along with other recyclable materials.

Collection is crucial because the industry has a recycling capacity that exceeds current usage. In fact, 11 billion PET bottles could be recycled annually but unfortunately end up in incinerators or landfills.

Step 2 – Sorting

At the recycling facility, the various recyclable materials are separated, with glass and metal being directed to their own recycling streams.

Once all non-plastic waste is removed, high-value recyclable plastics like PET are separated using automated systems or sometimes manually. The presence of other plastics would contaminate the PET recycling process, limiting its quality for reuse, reducing process efficiency, and increasing waste.

Step 3 – Transport

Once collected, PET is compressed to facilitate transport. PET has advantages over other recyclable packaging materials because it is extremely lightweight and can be compressed into small bales. This reduces emissions related to transport.

Step 4 – Treatment

These compressed bales of PET bottles are then sent to a processing center. Here, the bottles are processed to be transformed into recycled PET (rPET) ready to be reformed into packaging. The PET bottles are separated based on their color, then ground into crushed flakes.

Step 5 – Cleaning

The PET flakes are then cleaned as they contain ground caps, rings, and even labels. The cleaning process removes them, along with other contaminants such as glue.

The flakes are then dried before being heated to temperatures between 390°F and 460°F. The PET is kept at this temperature for several hours to decontaminate it, ensuring its safe use in food packaging after recycling.

Step 6 – Extrusion

After decontamination, the heated material is drawn into long, thin strands of clear PET. These are then cooled and provide pure PET ready to be cut into small pieces resembling crystals.

Step 7 – Remelting

The recycled PET is then sent by manufacturers to be used by the packaging industry.

First, PET pellets are transformed into preforms ready to be turned into new bottles and sent to bottle manufacturers who do not produce their own preforms. These PET preforms are heated, then shaped to the desired size and form.

The cycle of transforming bottles into bottles is thus closed, ensuring a more sustainable future for packaging.

The use of recycled PET in food packaging is perfectly safe and has been approved by organizations and governments worldwide.

The Transformation of Recycled Plastic #1 (PET) into New Products

Recycled PET (Polyethylene Terephthalate) is transformed into a wide range of products, showcasing the versatility and value of recycling. Some of the common products made from recycled PET include:

- Fiber for textiles, which is used in carpets, clothing, and other fabric items.

- New PET containers for food and beverages, continuing the cycle of use in a sustainable manner.

- Construction materials, such as insulation and piping, demonstrating PET’s utility beyond just packaging.

Recycling PET containers is a crucial step in giving these materials a second life, significantly reducing environmental impact. It’s an effective way to contribute to a sustainable future by minimizing waste and promoting resource efficiency.

FAQs

We’ll explore questions frequently asked here, shedding light on various aspects of Plastic #1 (PET).

Is Plastic #1 Microwave Safe?

Plastic #1 is a common component in items like plastic bottles and various food packaging, such as oil bottles, blister packaging, and bottled water. While it’s deemed safe for single-use applications, it’s essential to understand that PET is not recommended for microwave use.

In fact, this caution applies to all types of plastics, regardless of what manufacturers may claim or advise.

The reason for this caution lies in the potential for chemical leaching when PET is microwaved, posing possible health risks.

A healthy and preferable solution is to transfer the contents into a glass container before microwaving. This simple step can significantly mitigate any risk, ensuring a safer way to heat food or liquids. It’s a practice widely recommended for those looking to avoid any potential hazards associated with microwaving plastics.

What Happens When PET Isn’t Recycled?

As an environmentally conscious individual, it’s clear that failing to recycle PET can significantly impact our environment. When PET is not recycled, it often ends up in landfills, where it can take years to decompose. Even more concerning is PET waste in oceans and other bodies of water, which poses serious threats to marine life.

Recycling PET products helps reduce the demand for new plastic production, thereby conserving valuable resources like oil. In many urban areas, such as New York, recycling facilities readily accept PET, and finding a recycling bin for this material is usually straightforward.

A simple yet effective way to contribute is by ensuring that PET items, like plastic bottles, are clean and free from any residue before recycling them. This small step aids in a cleaner and more efficient recycling process. Additionally, recycled PET finds new life in various products, including polyester fibers and new bottles.

Remember, always check the recycling symbol on packaging to see if it can be recycled in your area. Adhering to proper recycling guidelines is crucial for maintaining a cleaner environment and ensuring a sustainable future for everyone.

Conclusion

As we reach the conclusion of this article, I hope it has enhanced your understanding of Plastic #1 (PET), the most widely used and recycled type of plastic around the globe.

If you have any further questions or insights about PET recycling or related topics that this article didn’t cover, please feel free to reach out. Your engagement is vital to continuing this important conversation.

Sources